Weighing and Dispensing of Raw Material

The solution for weighing and dispensing

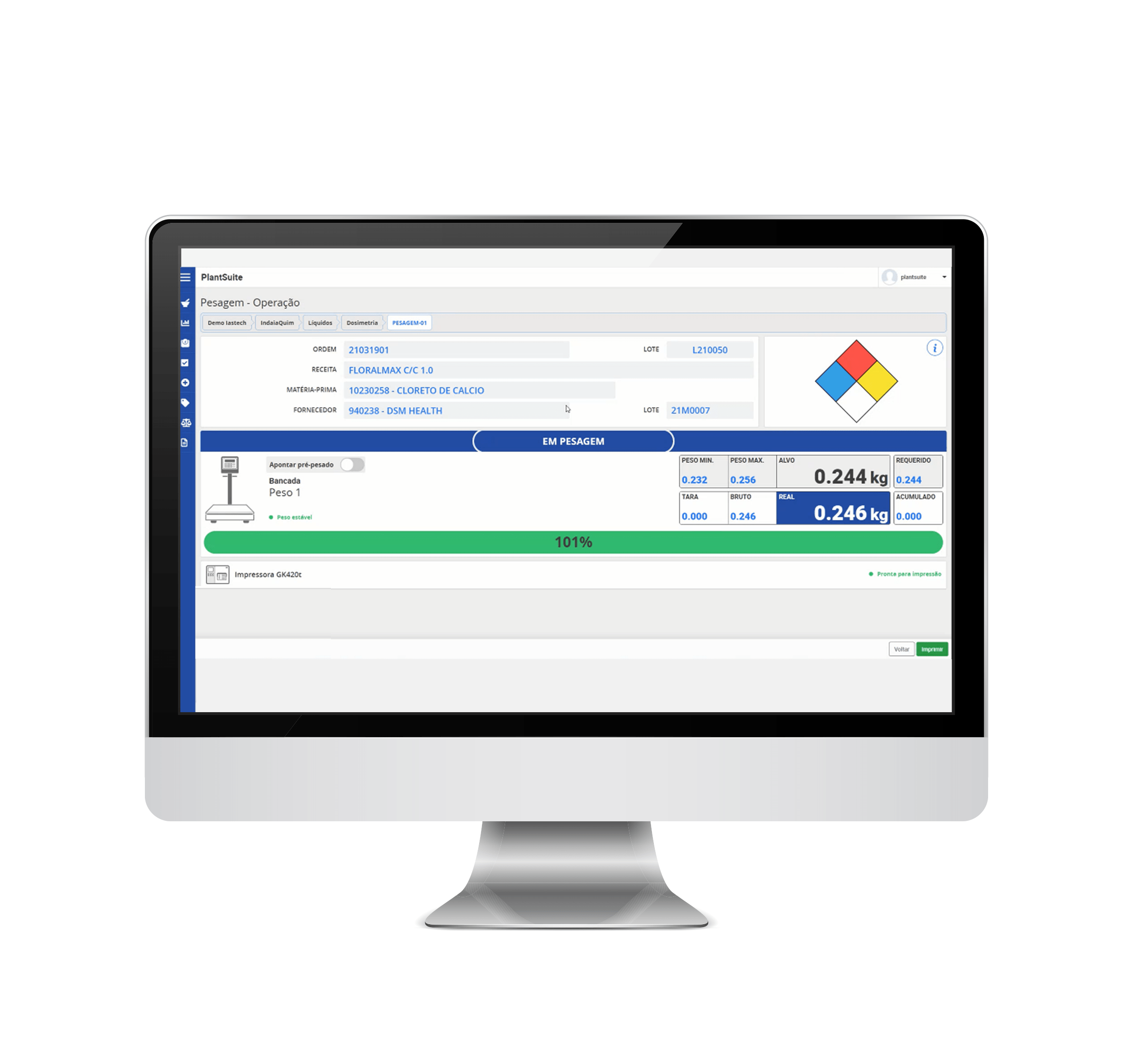

PlantSuite W&D®: Digitalize, control and track the weighing process in real time

IASTECH offers the best solution to digitize the process of weighing and dispensing critical ingredientes and microingredients, mainly for the pharmaceutical, cosmetics, and food industries.

- Intuitive interface and 100% web (local and cloud)

- Devices: RF handhelds, tablets, IHMs

- Batch and campaign wheighing

- Pre-weighing of the frequent used ingredients

- Full or partial check-out

- Full or partial check-in

- Addition control via RF collector

- Ingredientes inventory control by package

- ERP integration

Produce 100% according to the recipe

Maximize Weighing & Dispensing process

The PlantSuite W&D ® eliminates manual and paper records processes, reducing erros and material variability in the Weighing and Dispensing processes. The ingredients and microingredients are critical, expensive and can also be highly hazardous, thus it must be precisely measured according to the recipe indicated. The W&D process set up the foundation of the final product and the level of security in the process. Reduce waste. Be compliant to the security measures.

The extensive use of the bar code and QRCode labeling technology and the wireless handheld RF ensure the proper material correctly identified; the correct labeling of the weighed material bag and pallets; the correct quantity, according to the matching recipe, providing accuracy, agility and efficiency of the whole production process.

The extensive use of the bar code and QRCode labeling technology and the wireless handheld RF ensure the proper material correctly identified; the correct labeling of the weighed material bag and pallets; the correct quantity, according to the matching recipe, providing accuracy, agility and efficiency of the whole production process.

Main functionalities:

- Recipe Screen of Weighing

- Intuitive Weighing Screen

- Allocation of weighing by station and operator

- List of batches and ingredients for weighing

- Tolerance and validation of predefined raw materials

- 100% system integrated scales

- Devices: RF handhelds, tablets, IHMs

- Barcode and QR Code label printing

- Control for reprinting labels by the device

- Reading for validation of printed labels

Genealogy and traceability

PlantSuite W&D – Meeting regulatory requirements to ensure product quality excellence

Plantsuite W&D provides end-to-end control and traceability, from receipt of the raw materials to final product packaging.

- Dashboard: Real-time visibility of the workin-in-progress in the factory floor

- Historical record of weighing and additions process

- Traceability and control of ingredients packaging and final product

- Detailed traceability reports:

- Production Order/ Batch

- Operator

- Date/Time Weighing

- Ingredients

- Supplier’s Lot

- Weight

- Validity

- Real-time graphics of process variables Genealogy:

- Genealogy

- Recording of the ingredients, semi-finished products and final product

- Recording of the flow of equipment used